M-1 Flow Measurement

M-1 Flow Measurement

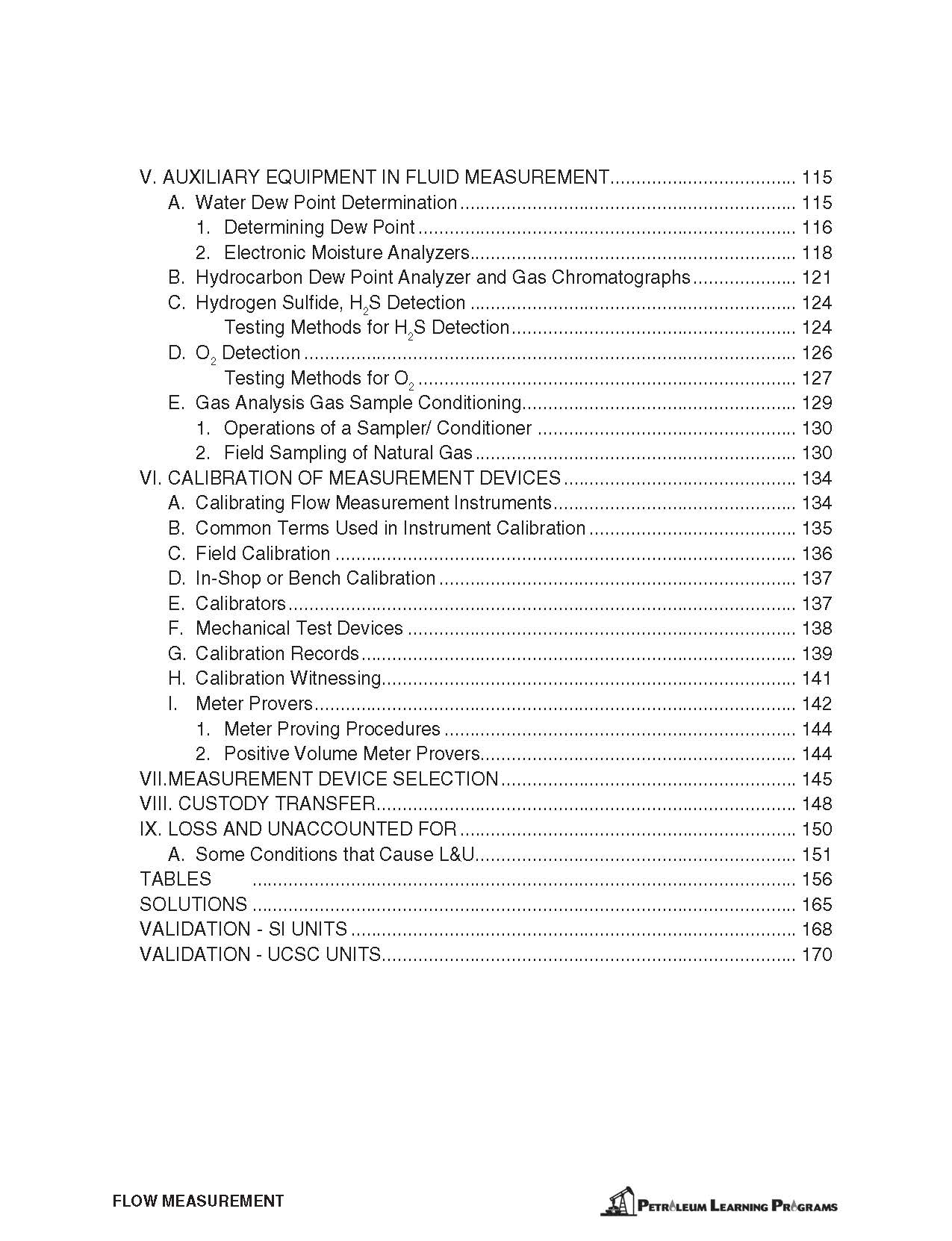

FLOW MEASUREMENT (175 pages with drawings, tables, illustrations, and examples for added comprehension) This training manual reviews the procedures for calculating natural gas and liquid flow through an orifice plate, use of turbine meter, positive displacement meters, UltraSonic meters, Coriolis meters and other devices used for measuring fluid flow. Both Metric and English units of measurement are used so students can work in units with which they are familiar.

Covered Subjects:

Principles of flow measurement

Units of measure for flow measurement and Standard Conditions

Types of fluid flow measurement devises and their principles of operations

The effect of temperature and relative density on measurement

The procedure to calculate natural gas flow through an orifice meter tube

Principles of operations for Ultrasonic, Coriolis and other type meters

Tables are provided for the coefficient, and correction factors for temperature, relative density, and supercompressibility

Drawings and photographs of various devices used in fluid flow measurement

Factors affecting accuracy of flow measurement

Instrumentation common at a meter location.

Meter provers

Meter calibration and witnessing

Loss and Unaccounted For

Questions and problems are included throughout the text with answers in the back that allow students to check their understanding of the subject.

Estimated self-study time: 20 hours

The M-1 Knowledge Validation Test provides the answers to both USCS and SI unit validation test questions in the manuals for self-grading or for supervisor to grade test of employees. Also included scoring information. Test answers in pdf format will be emailed.

Alternatively, PLP will review and score completed test. Contact PLP for pricing.

An experienced PLP instructor can travel to your site to lead a classroom training program. Contact PLP for more information.